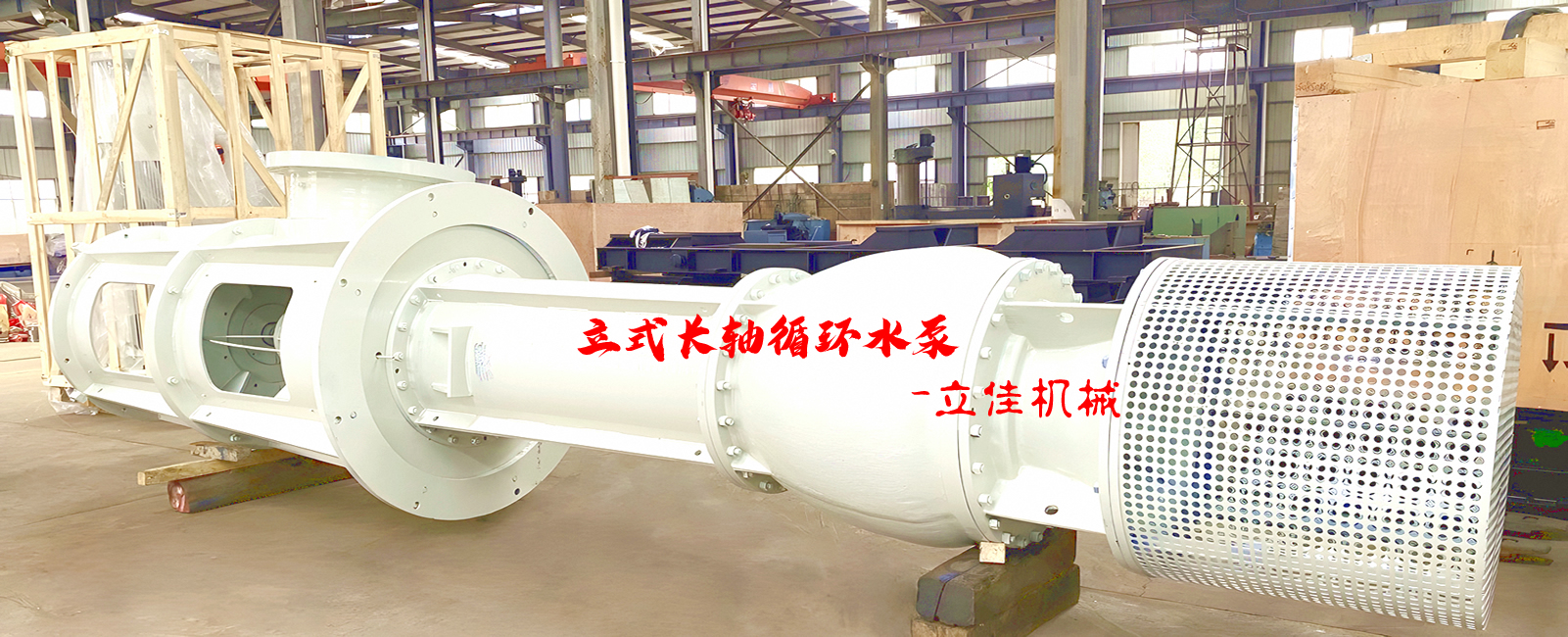

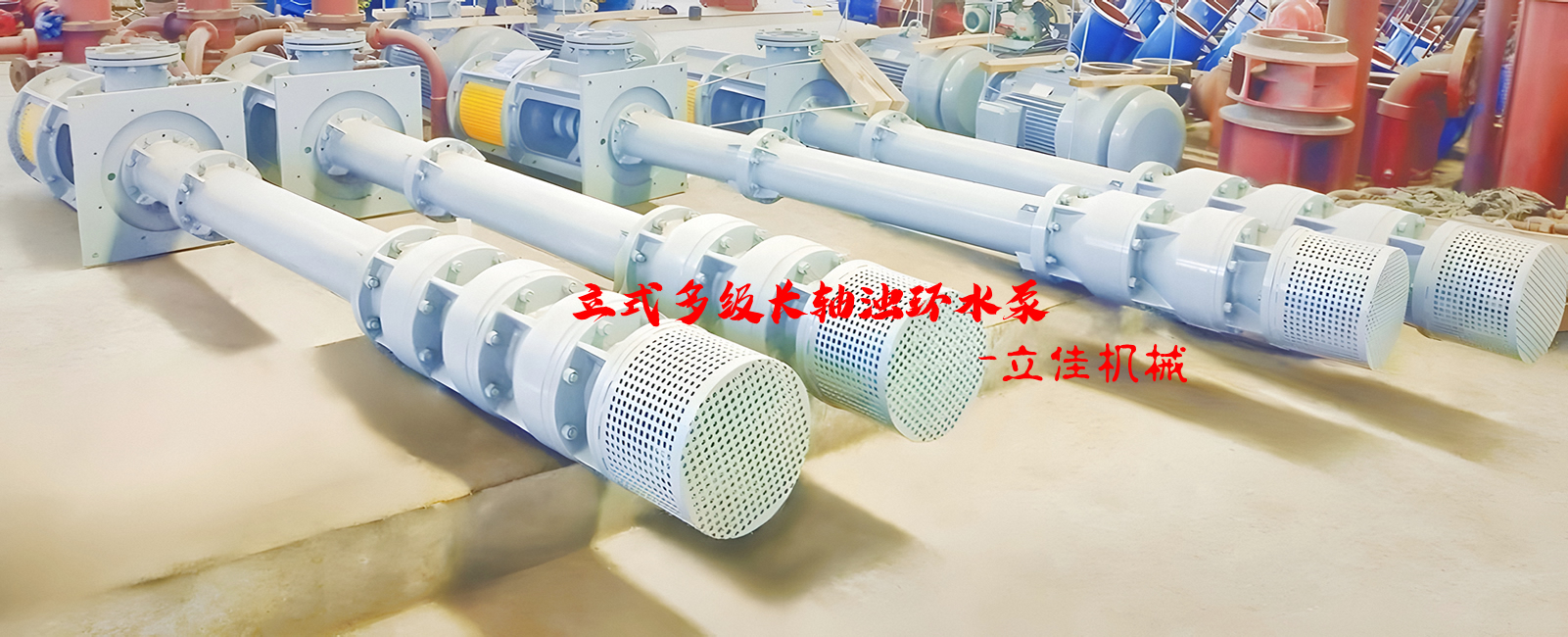

HLB(K)系列单壳体立式斜流泵

HLB、HLBK、HLKS、HLKT型立式斜流泵系立式单级导叶式混流悬臂式离心泵,为立式单级(多级)离心式或斜流式带导叶体结构,是我厂借鉴国际先进技术并结合我国实际,取长补短、研究开发的立式悬吊泵产品。

产品详情

HLB(K)系列单壳体立式斜流泵

概述

HLB、HLBK、HLKS、HLKT型单壳体立式斜流泵系立式单级导叶式混流悬臂式离心泵,为立式单级(多级)离心式或斜流式带导叶体结构,是我厂借鉴国际先进技术并结合我国实际,取长补短、研究开发的立式悬吊泵产品。供输送温度低于55℃的清水、雨水、海水及污水等。适合于电厂用作循环泵,也可作钢铁厂、船埠等工业用水、城市供水、排水工程和农田排灌等用。

型号意义

1600HLB(HLBK、HLKS、HLKT)-20

1600 —— 泵吐出口直径为1600mm

HLB —— 不可抽立式斜流泵

HLBK —— 可抽立式斜流泵

HLKS ——吐出口在基础层之上的可抽立式斜流泵

HLKT —— 叶片可调的可抽立式斜流泵

20 —— 泵设计点扬程为20m

性能范围

最大流量:25000立方米/小时(110000加仑/分)

最高扬程:70米(210英尺)

结构特点

1、安装方式

单层基础:电动机与泵直接安装在一个基础层上,泵吐出口可布置在基础层之下,也可布置在基础层之上。

双层基础:电动机与泵安装在各自的基础层之上,泵吐出口在两基础层之间。

泵安装型式有湿坑式安装或干坑式安装。

湿坑式安装:泵下部浸没在吸水池中。

干坑式安装:泵采用管道进水,泵吸入喇叭口与进水管道之间采用90°肘形进水弯管联接。

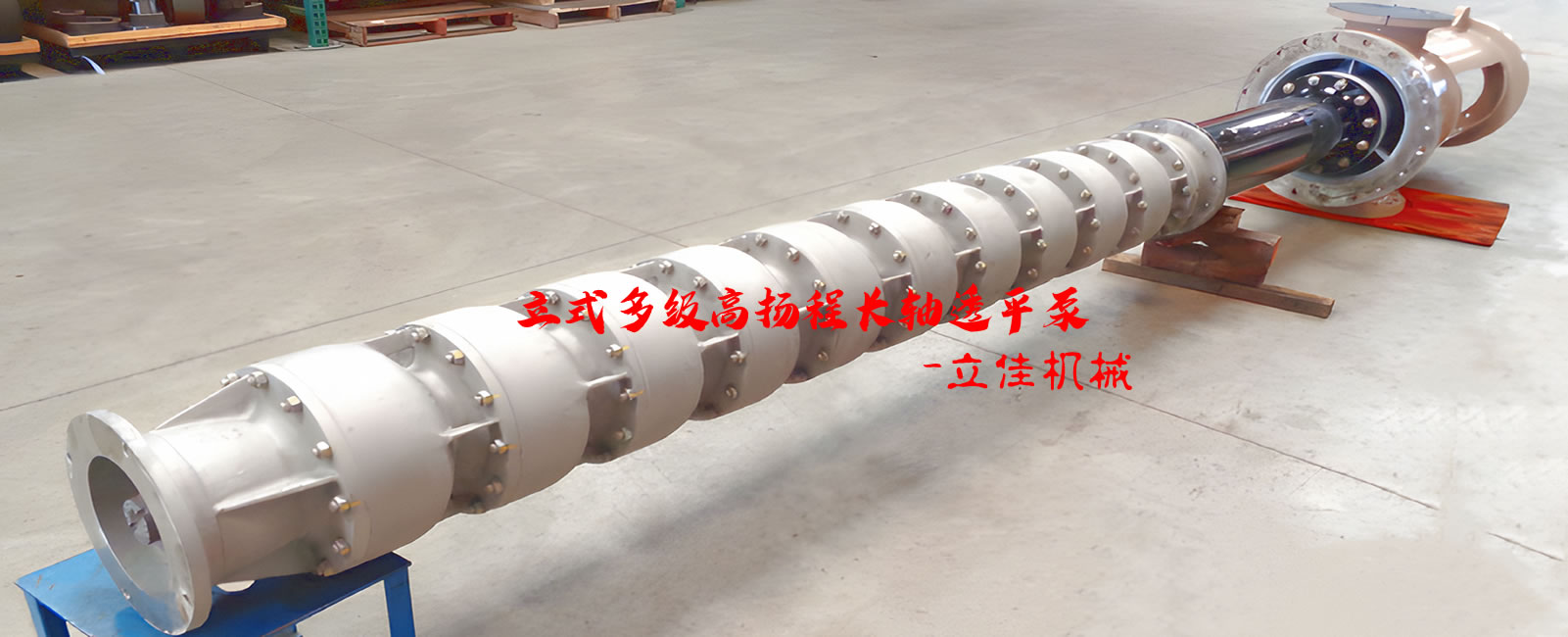

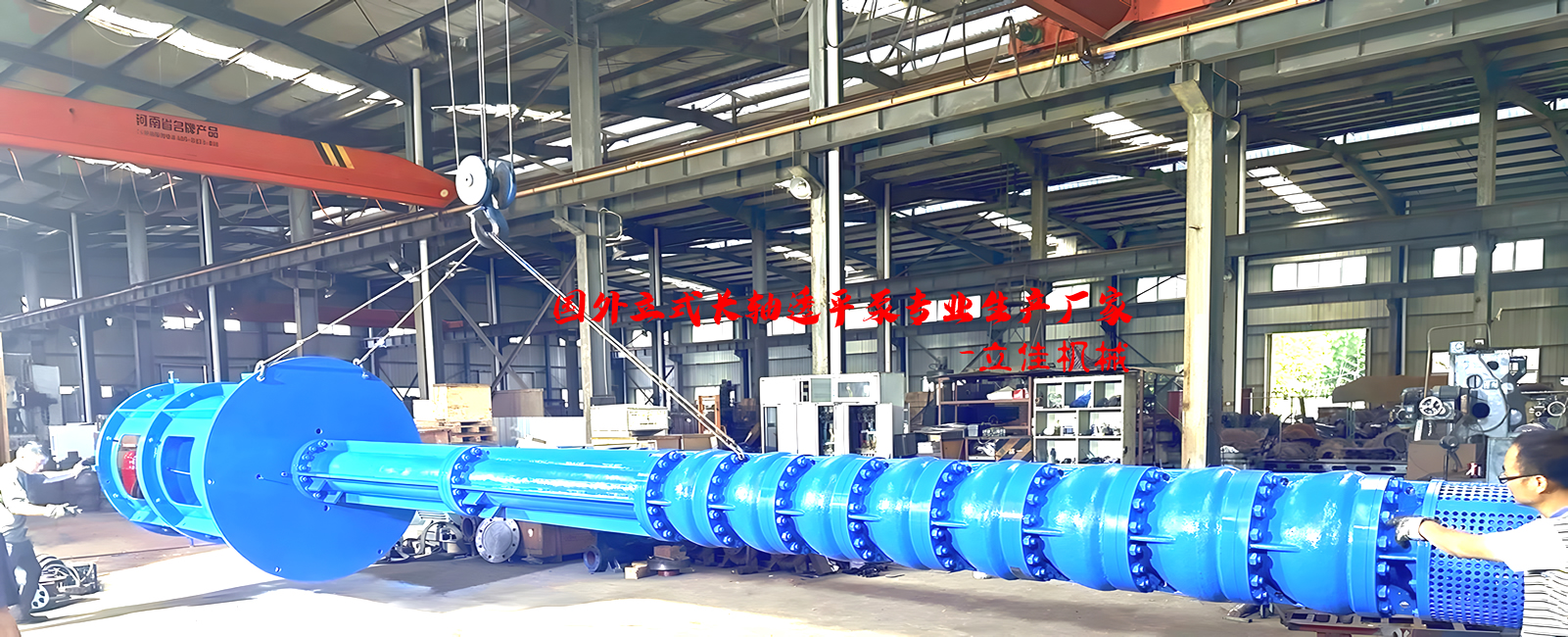

2、泵分为不可抽出式和转子可抽出式(包括导叶体)或泵整体可抽出式三种,泵口径在1000mm以下时,泵转子一般为不可抽形式;泵口径在1000mm以上时,泵转子一般为可抽形式。

3、泵叶轮分为整体叶轮或组合叶轮。

4、泵的轴向力由电机的止推轴承承受或泵的推力轴承承受,泵口径在1000mm以下时,泵轴向水推力及转子重量一般由泵本体推力轴承承受,泵和电机之间采用弹性联接,泵口径在1000mm以上时,泵轴向水推力及转子重量一般由电机推力轴承承受,泵和电机之间采用刚性联接;泵本体承受轴向水推力及转子重量时,泵推力轴承采用稀油润滑,推力轴承部件带Pt100测温元件测轴承温度或压力式温度计测润滑油温度。

5、泵的轴承为橡胶(耐磨、耐蚀、耐海水橡胶)导轴承和赛龙轴承。泵轴通常设置护管,护管内充有洁净的压力水,用于导轴承的润滑和冲洗,水量可由流量继电器控制,以防缺水损坏轴承。当泵用于输送污水或含有颗粒的水时,导叶体内的导轴承末端设有停车自动轴封装置,以防停机后介质进入轴承内;润滑形式有外接润滑水和泵自身润滑等形式。

6、输送海水的泵,除采用耐海水腐蚀的材料外,还采用牺牲阳极法和外部电源法阴极保护装置,以防止泵零件的电化学腐蚀。

7、泵通过刚性或弹性联轴器由电机直接驱动。

8、泵吸入口有通常的喇叭形或改进的椭圆导流墩两种。

LB型不可抽立式长轴单级离心泵结构简图:吐出口在基础层之上,泵承受轴向水推力及转子重量。

LB型不可抽立式长轴多级离心泵2级结构简图:吐出口在基础层之上,泵承受轴向水推力及转子重量。

|

LK型转子可抽出式立式斜流泵结构简图:吐出口在基础层之上,泵承受轴向水推力及转子重量。

LK型转子可抽出式立式斜流泵结构简图:吐出口在基础层之下,电机承受轴向水推力及转子重量。

产品特点

1、 运行平稳,安全可靠,免抽真空启动,使用寿命周期长。

2、 泵体积小,基础占地面积少,基础以下泵长度可以调整,适应性强。

3、 流道简单可靠,节省泵房基建投资。

4、 结构合理,装拆方便,维护检修容易简便。

5、 泵效率高,降低运行成本

型谱图

材 料

输送介质 | 清水 | 海水 | ||

材料类别 零件名称 | Ⅰ | Ⅱ | Ⅲ | Ⅳ |

吸入喇叭口 | HT250 | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

叶轮室 | ZG1Cr13Ni1或 ZG1Cr18Ni9 | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

叶轮 | ZG1Cr13Ni1或 ZG1Cr18Ni9 | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

导叶体 | HT250 | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

外接管 | Q235-A | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

出水弯管 | Q235-A | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

连接管 | Q235-A | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

导流壳 | Q235-A | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

中间轴承座 | HT250 | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

护管 | Q235-A | 0Cr18Ni9 | 00Cr17Ni14Mo2 | 00Cr22Ni5Mo3N |

轴 | 45或35CrMo | 0Cr17Ni12Mo2 | 0Cr17Ni12Mo2 | 00Cr22Ni5Mo3N |

轴套 | 45镀铬或2 Cr13 | 1Cr17Ni2 | 1Cr17Ni2 | ZG00Cr22Ni5Mo3N |

导轴承 | 橡胶或赛龙 | 橡胶或赛龙 | 橡胶或赛龙 | 橡胶或赛龙 |

套筒联轴器 | 45或2Cr13 | 1Cr17Ni2 | 1Cr17Ni2 | ZG00Cr22Ni5Mo3N |

联轴器 | ZG230-450 | ZG230-450 | ZG230-450 | ZG230-450 |

盖板 | Q235-A | HT250Ni2Cr | ZG00Cr17Ni14Mo2 | ZG00Cr22Ni5Mo3N |

电机座 | Q235-A | Q235-A | Q235-A | Q235-A |

注:HLB(K)系列单壳体立式斜流泵各零件材料可根据用户要求另行商定。